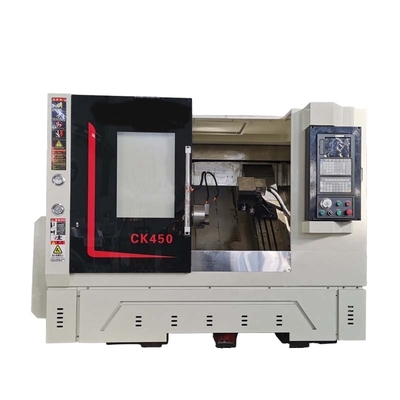

Condition:

New

Type:

Horizontal

Max. Length Of Workpiece (mm):

1000 Mm

Structure:

Slant Bed Lathe

Max. Spindle Speed (r.p.m):

2000 R.p.m

Machining Capacity:

Medium Duty

Spindle Bore(mm):

82 M'm

Width Of Bed (mm):

400 Mm

Spindle Motor Power(kW):

7.5

No. Of Spindles:

Single

Max. Turned Length (mm):

850

Number Of Axes:

2

Travel (X Axis)(mm):

295 Mm

Travel (Z Axis)(mm):

900 Mm

Positioning Accuracy (mm):

0.03 Mm

Repeatability (X/Y/Z) (mm):

0.012

Dimension(L*W*H):

2810*1600*1620MM

Voltage:

Customer's Requirement

CNC Control System:

FANUC

Toolpost Brand:

Hongda

Tool Post Stations:

6, 4

Weight (KG):

2420

Warranty:

1 Year

Applicable Industries:

Machinery Repair Shops, Manufacturing Plant, Home Use, Retail, Construction Works , Energy & Mining

Key Selling Points:

High-accuracy

Showroom Location:

Egypt, Canada, Algeria

Marketing Type:

New Product 2021

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Motor, PLC, Gearbox

Max.cutting Dia. For Disc Parts:

300mm

Max.cutting Dia. For Axle Parts:

135mm

Max. Length Of Workpiece:

500mm

Max Turning Length:

390mm

6-way Turret Max Turning Length:

340mm

Spindle Nose:

D4 Or A2-5

Spindle Bore:

38 Or 43mm

Taper Bore Of Spindle:

M.T.NO.5 Or 40° Tapper

Rapid Feed For Axis X:

8m/min

Rapid Feed For Axis Z:

10m/min

After-sales Service Provided:

Online Support, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Egypt, Canada, Algeria

Certification:

CEISO9001:2008

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!